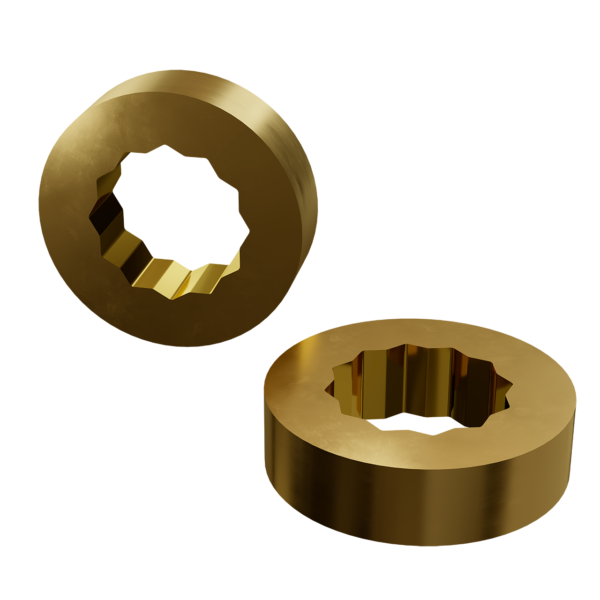

Cutting & trimming dies cutting

The manufacture of cutting and trimming dies with different profiles is carried on high precision grinding centres, high-speed machining centres, wire and electrode EDM and CNC lathes for hard lathing (steel and carbide) based on TEMSA’s technology. The technical department will help selecting the most suitable steel or carbide tool for the material to be cut.

A young and expert team, using state-of-the-art CAD-CAM software, such as POWERMILL, MASTERCAM, FIKUS & SIMCT, supported by modern simulation software, will develop the necessary programs that make possible generating the requested profiles.

All possible profiles are generated

by the completely standardized and

automated erosion and machining

centres.

Advice on carbide and steel grades for different applications.

Advice on carbide and steel grades for different applications. Perfect tangent radius.

Perfect tangent radius. Mechanical Processing surfaces when it is geometrically possible.

Mechanical Processing surfaces when it is geometrically possible. Large number of shapes with very high geometric complexity.

Large number of shapes with very high geometric complexity. Coating, the most suitable for the materials to be cut.

Coating, the most suitable for the materials to be cut. Mirror polishing before and after coating.

Mirror polishing before and after coating. CAD-CAM in all machining processes.

CAD-CAM in all machining processes. ± 0.005 mm tolerances.

± 0.005 mm tolerances.