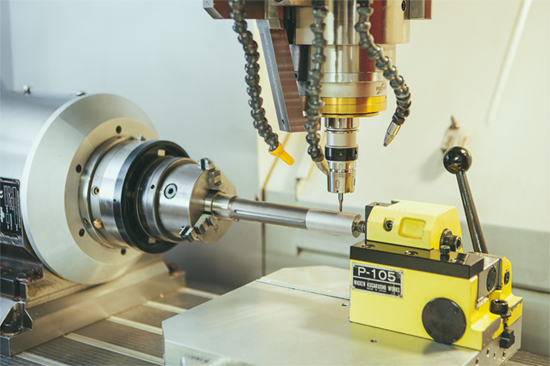

TEMSA is a company that has always bet on technology as being the starting point to go further. Since 2008 a large part of the budget has been invested in machinery to become a worldwide technological reference in the manufacturing of special single unit parts just in time.

TEMSA has always known to identify its clients’ needs and that one of those is to be a technological ally for their tools needs. This wouldn’t be possible if it weren’t for the powerful machinery used by highly trained team. Our production staff, who is young yet have considerable experience in the sector, are constantly experimenting with how to obtain the greatest benefits from each and every machine available.

We are pleased to announce our participation in the Resqtool program, a program that will offer a sustainable and energy-efficient solution for the recycling and responsible supply of critical raw materials (Co, W, Ta, Ti, Nb) from end-of-life products in the metal and wood cutting, construction, and manufacturing industries. This will help reduce the carbon footprint of the zinc recovery process and develop advanced hydro- and solvometallurgical chemical recycling based on bioderived chemicals from agroindustrial waste.

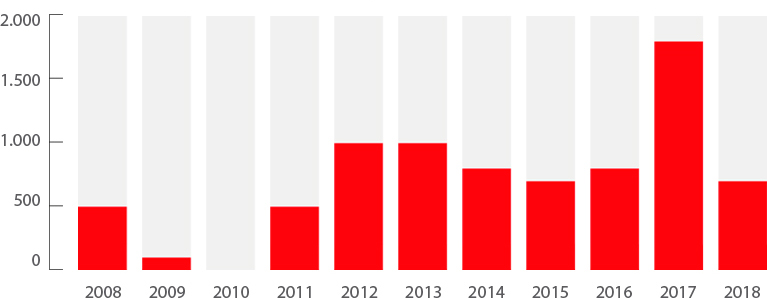

DEVELOPMENT OF INVESTMENTS

(Thousands of euros)

WIDE VARIETY OF PROCESSES

The secret to success isn’t only in having powerful machinery, but in dominating all of the processes and applying them when they should be used. In this way TEMSA provides a large variety of CNC processes which allows us to implement a multitude of solutions adapted to each tool. Soft and hard turning, internal and external grinding machines, robot cells, EDM by penetration, wire EDM, hard high speed machining with 3 or 4 axes, are applied depending on requirement of the tool and in a controlled flow by the ERP created by TEMSA which allows 100% traceability and an analysis of the process which few companies in our sector are able to offer.

The future is just around the corner. The R&D teams from the company are now working on new production processes so that they can be put to use soon. For that reason regular visits are made to the facilities of the leading suppliers of machinery in the market to find the machines best adapted to the needs of the company, and only for their clients.

MACHINERY LIST:

· Wire EDM CNC – 5

· Spark EDM CNC – 4 + 2 Robots

· High speed milling – 5 + 2 Robots

· Internal grinder (only CNC) – 6

· Internal grinder robot cell – 1

· External grinder (only CNC) – 2

· External grinder for punches with robot – 2

· Plane surface grinding machine – 3

· Hard turning CNC lathes – 4

· CMM – 4

· Profilometer (contracer) – 4

· Hard CNC lathes – 4

· Three-dimensional verifiers – 4

· Profilometers – 4

Horizon Europe project RESQTOOL

TEMSA takes part in the Horizon Europe project RESQTOOL, for recycling of high quality CRM resources from machining tools for re-use applications. TEMSA, as a tool producer, is a key partner in order to adjust all interests and gather forces to achieve a more sustainable world.

Description

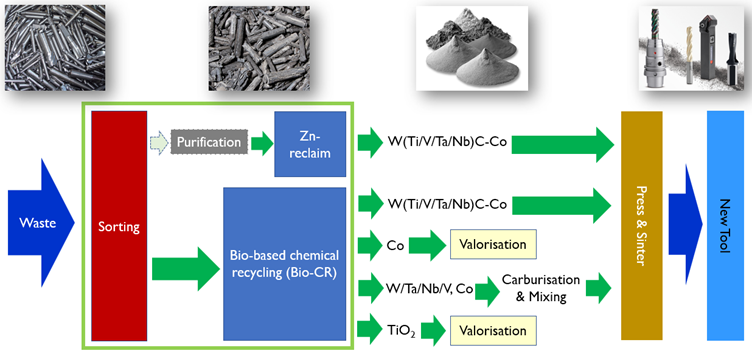

RESQTOOL is a Horizon Europe project that will offer a sustainable and energy efficient solution for recycling and responsible supply of Critical Raw Materials (Co, W, Ta, Ti, Nb) from End of Life products in metal/wood cutting, construction and manufacturing industries by lowering the carbon footprint of Zinc Reclaim process and developing advanced hydro- and solvo-metallurgical chemical recycling based on agro-industrial waste-bioderived chemicals.

Hardmetals (HM) form nowadays the backbone of the tool manufacturing industry with diverse applications and show a wide range in terms of combination of high hardness and toughness. This makes them suitable for many wear applications such as machining of metallic and non-metallic materials, chipless forming, mining, industrial nozzles and wear parts, dental and medical tools, paper, plastic and textile knives, guide rolls, seal rings, tire studs, forestry and agriculture tools, earth moving and consolidation tools, plus many others.

METHODOLOGY

RESQTOOL will identify HM scrap sources by their initial Industry uses. This will serve for identification of a certain recycling code for each group to be used in determining their recycling scheme. Then sampling protocols and methodologies to quantify CRM resources in specific products will be setup and used to collect HM scrap samples from the entire EU zone. Collected materials will be investigated to determine the size and shape distribution, elemental composition, origin, mass, and other physical parameters important for its segregation and recycling. Every group will be forwarded to a certain recycling scheme

IMPACT

- Higher re-use of raw materials and resources with reduced environmental impact and lower costs as demonstrated by Life Cycle Assessment

- Responsible supply of critical raw materials to Europe in line with the EU principles for sustainable raw materials through application of a circular economy

- Contributing to EU climate neutrality objectives by decreasing level of resource and energy consumption leading to a lower CO2 footprint

- Increase productivity, innovation capacity, resilience, sustainability and global competitiveness of European energy intensive industries

- Determination of requirements for sustainable critical raw materials recovery and processing in Europe in terms of social, environmental and economic performance

- Contributing, change to contribution; CO2

- Increase of productivity

Project number: 101138144

Project name: Recycling of High Quality CRM Resources from Machining Tools for Re-use Applications

Project acronym: RESQTOOL

Topic: HORIZON-CL4-2023-RESILIENCE-01-05

Type of action: HORIZON EUROPE – Innovation Actions

Granting authority: European Health and Digital Executive Agency

DURATION: 4 Years

PERIOD: 01 December 2023 – 30 November 2027

BUDGET: 8,8 M€

FULL RANGE SUPPLIER

TEMSA is a supplier which specializes in covering all of the business areas in its sector: the design and installation of the production processes for its clients; manufacturing the necessary tools for such processes; and the production of raw material for the tools.

INTERNATIONAL PRESENCE

Our commercial network reaches all corners of the planet. TEMSA exports more than 70% of its production.