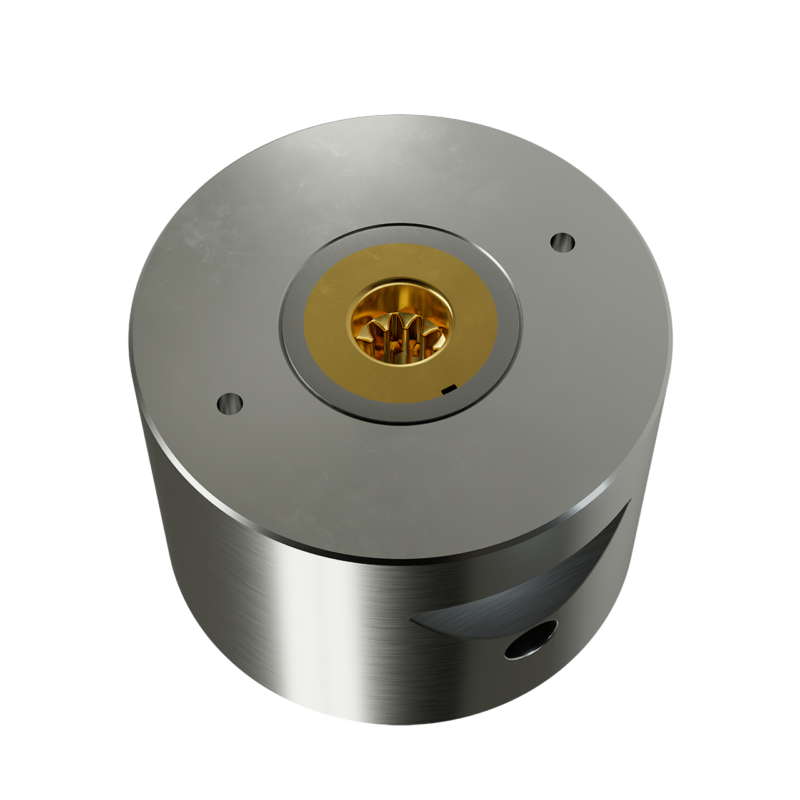

Dies with special profiles

Any profile you can imagine will come true in TEMSA. The special profile tools are helpful to go beyond on cold forming. TEMSA has added new CNC grinding centres with the technology needed to rectify irregular shapes and parts with strict tolerances that complemented erosion centres make it possible developing any type of profile.

A young and expert team is exclusively dedicated to developing CAD-CAM programs that will make possible to generate any figure, however difficult it may seem. The whole process is standardized and automated, thus reducing human action on the machine.

CAD-CAM, PowerMILL, MASTERCAM,

FICUS and SIMCT make possible the

execution of complex shapes and profiles

in the erosion, grinding and machining

centres.

Advice on carbide and steel grades for different applications.

Advice on carbide and steel grades for different applications. Mechanical processing of surfaces when it is geometrically possible.

Mechanical processing of surfaces when it is geometrically possible. EDM and wire-EDM standardized and automated.

EDM and wire-EDM standardized and automated. Complex electrode EDM machining with perfect concentricity and alignment between profiles.

Complex electrode EDM machining with perfect concentricity and alignment between profiles. Large number of shapes with very high geometric complexity.

Large number of shapes with very high geometric complexity. Mirror polishing before and after coating.

Mirror polishing before and after coating. Possibility of steel dies with pressed and grinded shapes, not eroded.

Possibility of steel dies with pressed and grinded shapes, not eroded. CAD-CAM in all machining processes.

CAD-CAM in all machining processes.