Extursion dies

Over the past 25 years TEMSA has developed its own state-of-the-art technology in order to improve tools’ lifespan whilst keeping costs down.

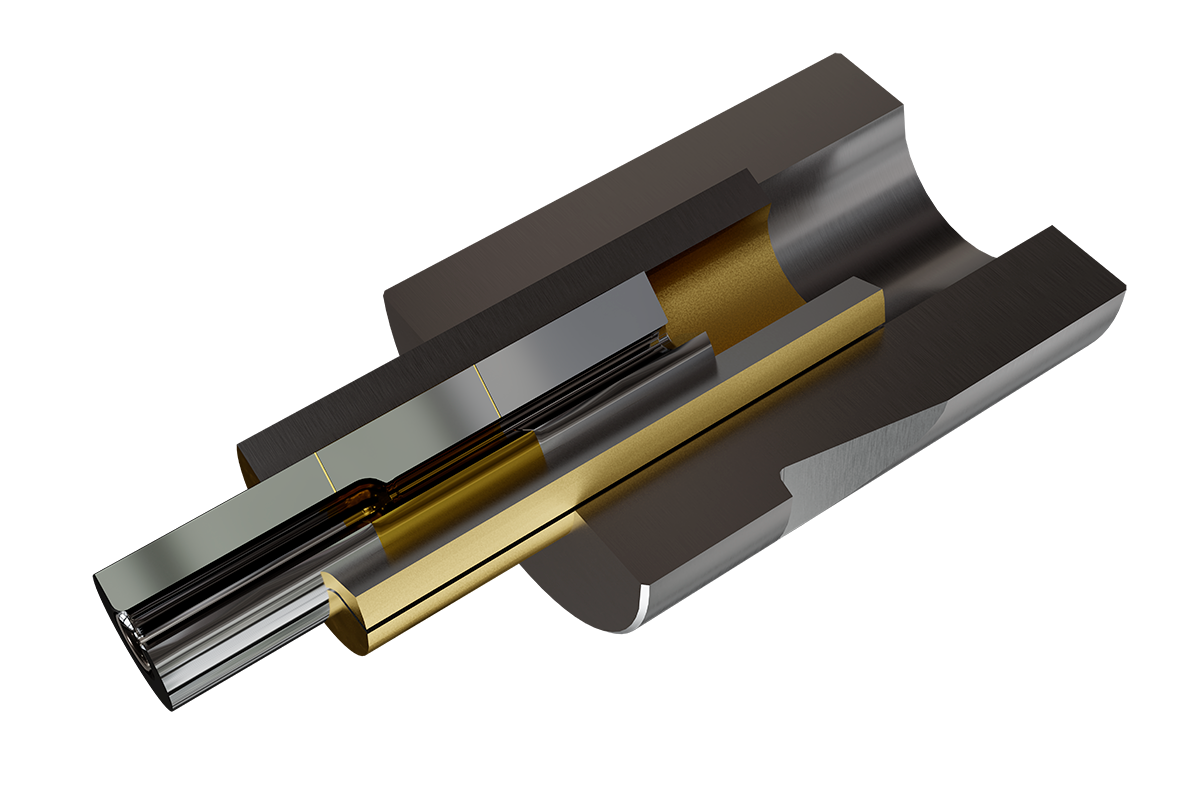

This die design technology allows the use of interchangeable carbide nibs and a PVD-TiN coating on the working area. On extrusion dies, a well-polished surface is essential: At TEMSA, the mirror polishing is done before and after PVD coating. This grants a better flow of the material, extending the tool’s lifespan and preventig the die from seizing-up.

Closed extrusion dies are used when more than 30% cross-section

reduction is needed.

TEMSA’s split nib technology. Air vents designed to reduce pressure. PVD coating can be applied in the reduction area. Different carbidegrades in order to improve tool performance. The coating improves the flow and prevents material to adhere on the tool.

TEMSA’s split nib technology. Air vents designed to reduce pressure. PVD coating can be applied in the reduction area. Different carbidegrades in order to improve tool performance. The coating improves the flow and prevents material to adhere on the tool. Conical nib for easy removal and replacement of nibs using the same casing.

Conical nib for easy removal and replacement of nibs using the same casing. Double high-speed steel hoop to fasten the nib and to hold radial tension. Outer conical shape and PVD TiN coating for easy removal and replacement of nibs using the same casing.

Double high-speed steel hoop to fasten the nib and to hold radial tension. Outer conical shape and PVD TiN coating for easy removal and replacement of nibs using the same casing. Open hoop for easy replacement of nibs and to increase interference.

Open hoop for easy replacement of nibs and to increase interference. Carbide grades: different carbide grades for anoptimum performance, G30, G20, G10 and submicron grain size.

Carbide grades: different carbide grades for anoptimum performance, G30, G20, G10 and submicron grain size. PVD, different coatings to be applied depending on the extruded material.

PVD, different coatings to be applied depending on the extruded material. Polishing before and after coating.

Polishing before and after coating.