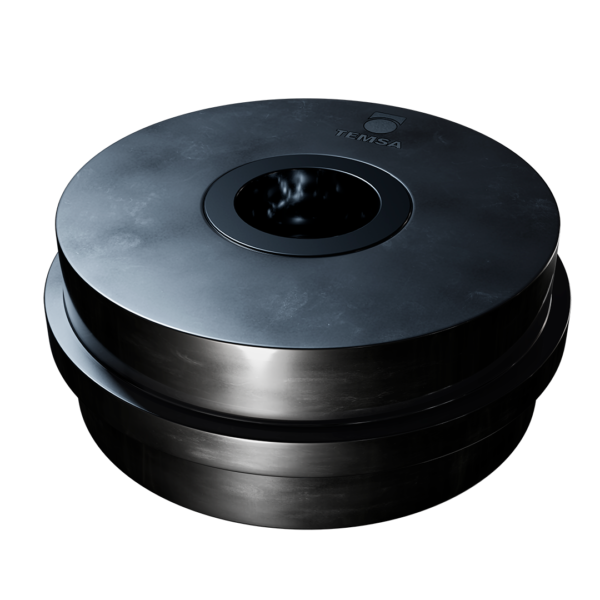

Dies

Dies are the main tool in the pressing and calibrating process. It is subjected to several different forces, wear being the main issue in need of resolution. To manage this, tungsten carbide, in all its different forms is the most popular material used in the construction of this tool. TEMSA is an expert in tungsten carbide machining, and has gathered extensive experience in all processes: machining, turning, grinding and EDM, to achieve the perfect contour and surface finishes.

When accuracy becomes art:

modern equipment of high-speed

machining and accuracy turn

the tool into a combination of

filigrees.

Advice in steel and tungsten carbide qualities for several applications:

Advice in steel and tungsten carbide qualities for several applications:·Tungsten carbide 15% Co fine grain 0,8 – < 1,3 [μm]: when geometries shapes have sudden section changes.

· Tungsten Carbide 6% Co fine grain 0,8 – < 1,3 [μm]: If maximum wear resistance is needed.

· CPM10V: high impact tolerance while keeping a good wear.

Mirror polish in surface finishes in order to avoid powder grip.

Mirror polish in surface finishes in order to avoid powder grip. Standardized and robotized EDM and Wire EDM processes. Tooling reworking and maintenance.

Standardized and robotized EDM and Wire EDM processes. Tooling reworking and maintenance. Possibility of high complex geometrical shapes.

Possibility of high complex geometrical shapes. ± 0.001mm tolerances.

± 0.001mm tolerances.