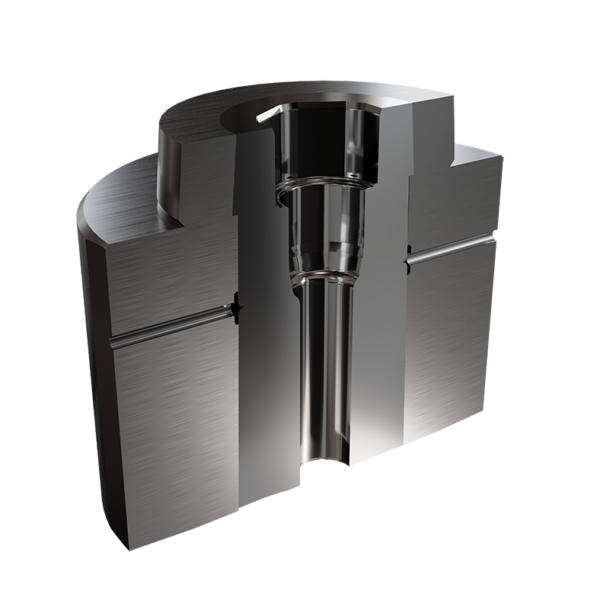

Reduction dies

In the processing of the reduction dies, TEMSA mechanically processes all surfaces wherever it is geometrically possible, thereby improving the lifespan of the tool. If EDM processing is unavoidable, TEMSA’s EDM department is fitted with modern electrode and wire-EDM equipment, both entirely robotized.

TEMSA reduction dies are polished before and after coating, resulting on the internal required polishing. All designs are checked to verify its feasibility before proceeding to manufacture. TEMSA advises clients whenever improvements could be performed or where errors in the drawings are detected.

TEMSA suggests and integrates, with considerable success, new carbide alloys for different types of dies for improved performance. A clear example of success is the end-reducing die after extrusion.

TEMSA is testing different alloys on

carbide dies, operating under great

stress or abrasion, substantially

improving their lifespan.

Advice on carbide and steel grades for different applications.

Advice on carbide and steel grades for different applications. Mechanical processing of surfaces when it is geometrically possible.

Mechanical processing of surfaces when it is geometrically possible. Air vents to evacuate air or oil pockets.

Air vents to evacuate air or oil pockets. TEMSA’s technology for split nibs: perfect concentricity.

TEMSA’s technology for split nibs: perfect concentricity. EDM and wire-EDM standardized and robotized.

EDM and wire-EDM standardized and robotized. Mirror polishing before and after coating.

Mirror polishing before and after coating. Possibility of steel dies with pressed and grinded shapes, not eroded.

Possibility of steel dies with pressed and grinded shapes, not eroded.